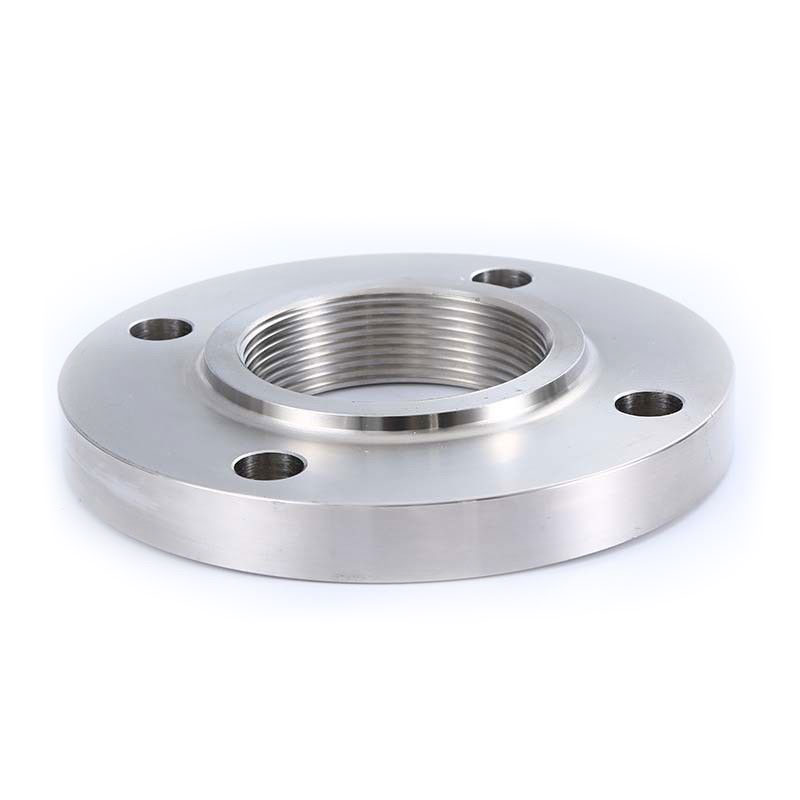

EN1092-01 Type 13 PN40 Carbon Steel/Stainless Steel Threaded Flange THRF

Stainless steel is an alloy of Iron with a minimum of 10.5% Chromium. Chromium produces a thin layer of oxide on the surface of the steel known as the passive layer. This prevents any further corrosion of the surface. Increasing the amount of Chromium gives an increased resistance to corrosion.

CONTACT US

Product Description

Product Description:

|

Product Name:

|

Threaded Flanges Raised Face

|

Product Standard:

|

EN1092-01(European Standard)

|

|

Material:

|

Carbon Steel, Also Include Stainless Steel, Alloy Steel And Others As Per Your Requirement

|

Product Face Type:

|

Mainly Include Raised Face (RF), Flat Face (FF), Also Include Ring Type Joint (RTJ), Lap-Joint Face (LJF) According To Different Customers’ Requirements

|

|

Pressures:

|

PN 40

|

Sizes:

|

DN 10 To DN 600

|

|

Export To:

|

Different European Countries And Other Countries Around The World

|

Apply For:

|

Plumbing, Oil And Gas, Chemical Processing, And General Industrial Piping Systems

|

A threaded flange is a type of flange designed with internal threads, allowing it to be connected to a threaded pipe without the need for welding. It offers the convenience of easy installation and maintenance, making it a suitable option in situations where welding is impractical or not possible.

In cases where alloy steel flanges have sufficient strength but pose challenges in welding or have poor welding performance, threaded flanges serve as a viable alternative. However, it’s important to consider the limitations of threaded flanges. They should not be used in applications involving sharp temperature changes or where the temperature exceeds 260°C or falls below -45°C, as this can lead to potential leakage issues.

Threaded flanges have a similar appearance to Slip-On flanges, but they are specifically bored to match the inner diameter of the pipe. The backside of the center opening is then threaded with tapered pipe threads of the appropriate size.

The primary advantage of threaded flanges is the absence of welding requirements, resulting in minimal additional torque applied to the pipe or barrel during flange deformation. However, threaded flanges tend to be thicker and more expensive compared to other flange types. They are particularly well-suited for high-pressure pipe connections.

EN1092-01 Carbon Steel Threaded Flange Dimensions:

| EN1092-01 Type 13 Threaded Flange PN 40 THRF | |||||||||||

| DN | Outside Diameter | O.D.of Raised Face |

Height of Raised Face |

Neck

Diameter |

Thickness | Dia Counter Bore | Length of Flange | Bolt circle diameter | Number of holes | Diameter of Bolt |

Radius of Corners

|

| D | G | f | X | t | B2 | T2 | K | Numbers | L | R1 | |

| 10 | 90 | 40 | 2 | 30 | 16 | 17.2 | 22 | 60 | 4 | 14 | 4 |

| 15 | 95 | 45 | 2 | 35 | 16 | 21.3 | 22 | 65 | 4 | 14 | 4 |

| 20 | 105 | 58 | 2 | 45 | 18 | 26.9 | 26 | 75 | 4 | 14 | 4 |

| 25 | 115 | 68 | 2 | 52 | 18 | 33.7 | 28 | 85 | 4 | 14 | 4 |

| 32 | 140 | 78 | 2 | 60 | 18 | 42.4 | 30 | 100 | 4 | 18 | 6 |

| 40 | 150 | 88 | 3 | 70 | 18 | 48.3 | 32 | 110 | 4 | 18 | 6 |

| 50 | 165 | 102 | 3 | 84 | 20 | 60.3 | 34 | 125 | 4 | 18 | 6 |

| 65 | 185 | 122 | 3 | 104 | 22 | 76.1 | 38 | 145 | 8 | 18 | 6 |

| 80 | 200 | 138 | 3 | 118 | 24 | 88.9 | 40 | 160 | 8 | 18 | 8 |

| 100 | 235 | 162 | 3 | 145 | 24 | 114.3 | 44 | 190 | 8 | 22 | 8 |

| 125 | 270 | 188 | 3 | 170 | 26 | 139.7 | 48 | 220 | 8 | 26 | 8 |

| 150 | 300 | 218 | 3 | 200 | 28 | 168.3 | 52 | 250 | 8 | 26 | 10 |

| 200 | 375 | 285 | 3 | 260 | 34 | 219.1 | 52 | 320 | 12 | 30 | 10 |

| 250 | 450 | 345 | 3 | 312 | 38 | 273 | 60 | 385 | 12 | 33 | 12 |

| 300 | 515 | 410 | 4 | 380 | 42 | 323.9 | 67 | 450 | 16 | 33 | 12 |

| 350 | 580 | 465 | 4 | 424 | 46 | 355.6 | 72 | 510 | 16 | 36 | 12 |

| 400 | 660 | 535 | 4 | 478 | 50 | 406.4 | 78 | 585 | 16 | 39 | 12 |

| 450 | 685 | 560 | 4 | 522 | 57 | 457 | 84 | 610 | 20 | 39 | 12 |

| 500 | 755 | 615 | 4 | 576 | 57 | 608 | 90 | 670 | 20 | 42 | 12 |

| 600 | 890 | 735 | 5 | 686 | 72 | 610 | 100 | 795 | 20 | 48 | 12 |

1.Dimensions are in millimeters(mm).

2.Dimensions can be specified by different purchasers.

Uses of EN1092-01 Carbon Steel Threaded Flanges:

Threaded flanges have a wide range of uses and are valued for their specific advantages. Here are some expanded and rephrased uses of threaded flanges:

Easy Installation: Threaded flanges are highly sought after because they can be fitted onto pipes of various sizes without the need for welding. This feature makes installation quick and straightforward, saving time and effort.

High-Pressure Applications: Threaded flanges are commonly employed in applications with extremely high pressure, especially when it is not feasible to perform post-weld heat treatment. These flanges provide a secure and reliable connection, even at or near atmospheric temperatures.

Small Diameter Piping: Threaded flanges are particularly well-suited for small diameter piping applications. Their threaded design allows for a compact and efficient connection in systems where space is limited.

Non-Cyclic Applications: Threaded flanges are primarily designed for non-cyclic applications, meaning they are intended for use in systems where there are no significant fluctuations in pressure or temperature. They provide a stable and secure joint for consistent operating conditions.

Hazardous Welding Environments: Threaded flanges find utility in environments where welding poses a hazard. In areas with high explosion risks or where welding is prohibited, threaded flanges offer a safe alternative for joining pipes without the need for welding equipment or specialized personnel.

Highly Explosive Areas: Threaded flanges are suitable for use in highly explosive areas where even the slightest spark from welding could ignite hazardous substances. By eliminating the need for welding, threaded flanges reduce the risk of ignition and ensure safety in such volatile environments.

Applications of EN1092-01 Carbon Steel Threaded Flanges:

EN1092-01 Carbon Steel Threaded Flanges find applications in various industries and piping systems. Here are some common applications where these flanges are used:

Plumbing Systems: Threaded flanges are frequently utilized in plumbing systems, such as water supply networks, wastewater systems, and irrigation systems. They provide a secure connection between pipes, valves, and fittings, allowing for easy installation and maintenance.

Industrial Pipelines: These flanges are suitable for industrial pipelines that transport fluids or gases, including oil and gas pipelines, chemical processing plants, power plants, and refineries. Their threaded connection enables a reliable joint that can withstand moderate pressure and temperature conditions.

HVAC Systems: EN1092-01 Carbon Steel Threaded Flanges are employed in heating, ventilation, and air conditioning (HVAC) systems. They connect pipes, pumps, and other HVAC components, facilitating the efficient transfer of hot or cold air throughout buildings or industrial facilities.

Process Piping: In various process industries, such as food and beverage, pharmaceuticals, and petrochemicals, threaded flanges are used for process piping. They provide a secure and easily detachable connection for conveying liquids, gases, or powders in manufacturing and production processes.

Water Treatment Plants: Threaded flanges are utilized in water treatment plants for connecting pipes and components in filtration systems, pumping stations, and distribution networks. They play a crucial role in ensuring the safe and efficient treatment and distribution of potable water.

General Industrial Applications: EN1092-01 Carbon Steel Threaded Flanges are used in a wide range of general industrial applications where a threaded connection is preferred or required. This includes equipment manufacturing, machine assembly, and various utility pipelines.